Quiet and Smooth Pavement Solutions for Your Concrete Surface Project

Ensure quiet pavement solutions wherever you need them with DSI’s Next Generation Concrete Surface (NGCS) services. Designed to reduce noise levels while maintaining traction and the smoothest ride, NGCS can be constructed quickly and efficiently without impacting roadway features such as curbs, guardrails, or barriers. As leading experts in NGCS, our experienced crews use a combination of diamond grinding and grooving on the concrete surface to achieve a flatter, smoother surface texture resulting in a safer, more enjoyable driving experience and better quality of life for nearby urban residents.

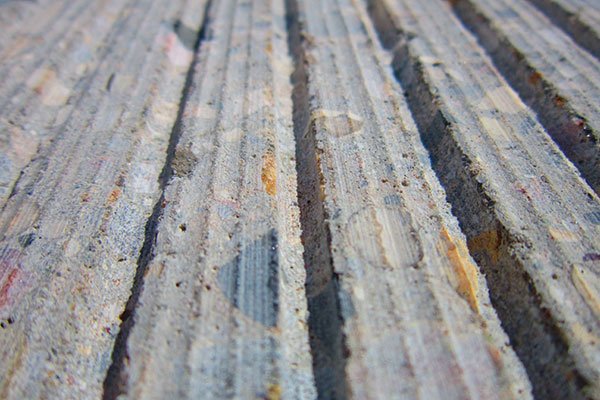

During NGCS, a thin layer of the existing concrete is removed using diamond grinding. The grinding process can be achieved in either a single or double pass operation. These diamond saw-cut surfaces are designed to provide a consistent profile absent of positive or upward texture. Since the NGCS is a “manufactured” surface, it is more consistent and predictable than most traditional surfaces.

The NGCS surface was developed through a partnership consisting of the IGGA, American Concrete Pavement Association (ACPA), Portland Cement Association and Purdue University. Extensive field testing and evaluation were conducted by MN/DOT Bat the MNROAD pavement research facility.

Key Advantages of NGCS:

- Reduced noise levels

- Improved traction and smoothest pavement possible

- Long-lasting solution

- Enhanced safety for motorists

- Less disruption to nearby urban residents

- Improved driving experience

- Customized solutions tailored to meet your specific needs and requirements